Blowing Jet Nozzles

viewed:185

Blowing Jet Nozzles

viewed:185

introduction

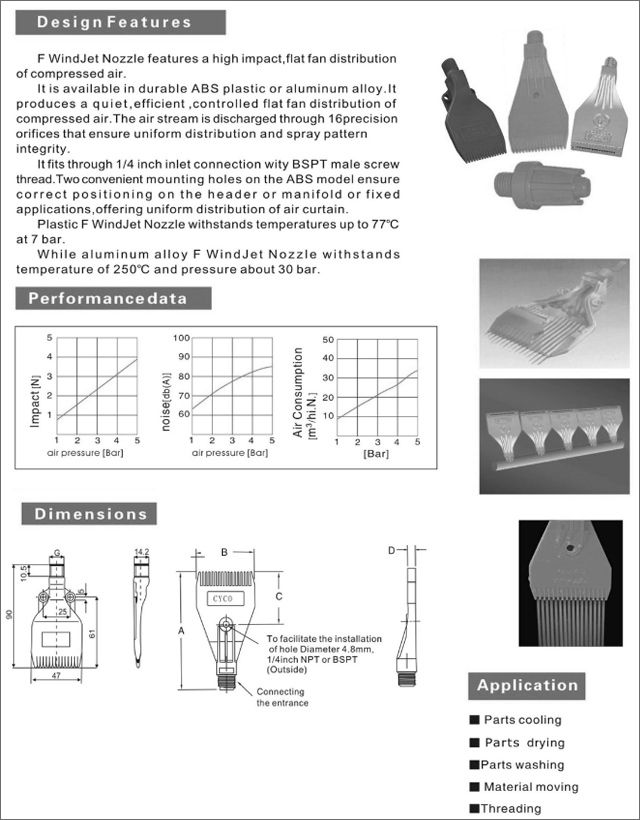

● The F series wind jet nozzle provides a high impact, flat fan and circular shaped air flow that designed for various air blowing applications in processing.

● This type of nozzle is mainly made of ABS or Aluminum Alloy, it is designed with multiple cylindrical spray holes to make a flat fan or circular shaped air flow. It consists with the principles of aerodynamics inside that can effectively reduce the air resistance during operation and meanwhile ensures a high blowing impact while the operation noise and air consumption are both decreased.

● The F series wind jet nozzle is mainly made as 1/4 inch BSPT male thread, 2 positioning holes on the ABS wind jet nozzle ensure the nozzles easier side by side installation to get an effective air curtain by combining such nozzles together.

● The plastic wind jet nozzle is able to bear the pressure of 7 bar, the temperature can be max 77 degrees under such pressure.

● The aluminum alloy wind jet nozzle is able to bear the pressure of 30 bar while the temperature can be max 250 degrees under such pressure.

● This type of nozzle is mainly made of ABS or Aluminum Alloy, it is designed with multiple cylindrical spray holes to make a flat fan or circular shaped air flow. It consists with the principles of aerodynamics inside that can effectively reduce the air resistance during operation and meanwhile ensures a high blowing impact while the operation noise and air consumption are both decreased.

● The F series wind jet nozzle is mainly made as 1/4 inch BSPT male thread, 2 positioning holes on the ABS wind jet nozzle ensure the nozzles easier side by side installation to get an effective air curtain by combining such nozzles together.

● The plastic wind jet nozzle is able to bear the pressure of 7 bar, the temperature can be max 77 degrees under such pressure.

● The aluminum alloy wind jet nozzle is able to bear the pressure of 30 bar while the temperature can be max 250 degrees under such pressure.